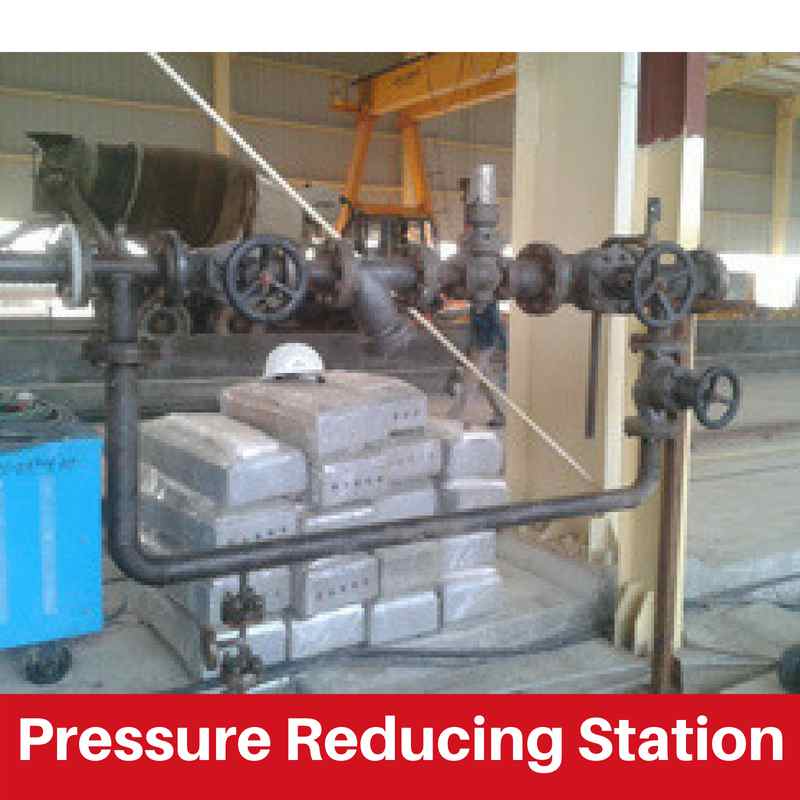

Steam Pressure Reducing Stations

Steam produced at a pressure in the Steam Boiler, might not be needed at that same pressure in the process machines. They need at a reduced pressure of steam to conclude the process. Here the Pressure Reducing Stations comes in handy as they help in achieving the desired steam pressure.Steam pressure reducing stations (PRS) are devices that are used to reduce the pressure of steam from a boiler to a lower pressure that is required by the process equipment. PRS are typically made up of a pressure regulator valve, a strainer, and a pressure gauge. The pressure regulator valve is used to control the flow of steam through the PRS, and the strainer is used to remove any impurities from the steam. The pressure gauge is used to monitor the pressure of the steam in the PRS.

Pressure reducing stations (PRS) is the arrangement of certain valves which is used to provide the desired steam pressure at user’s end. Steam coming from the Boiler, through the steam line, enters the PRS at a higher pressure and leaves the PRS at reduced (specified) pressure, in this the flow of the steam remains constant. Like Steam Boiler, PRS is also pressure equipment.

Thermodyne have designed, fabricated and successfully commissioned Pressure Reducing Stations (PRS) to many of our clients both across the country and abroad. This design has been incorporated with a high degree of reliable quality components for trouble-free service. Most of the process industries need steam at different pressures for different applications. Hence, a properly sized pressure reducing station (PRS) is required for efficient of steam with minimum losses.

Here are some additional benefits of using a steam pressure reducing station:

- Reduces the risk of steam leaks and explosions

- Improves the efficiency of steam systems by reducing the amount of steam that is wasted

- Extends the life of steam equipment by reducing the amount of stress on the components

- Provides a more consistent and reliable steam supply

- Can be used to meet specific steam pressure requirements for different applications

Advantages

- Rugged design

- Instance response to pressure changes

- Compact design

- Ready to install i.e. lower installation cost

- IBR and Non-IBR PRS are also available

- No maintenance cost

Search More Video: Thermodyne Boilers

Steam Pressure Reducing Stations FAQ

A pressure reducing station (PRS) is a device that reduces the pressure of a fluid from a high pressure to a lower pressure. PRSs are commonly used in steam systems to reduce the pressure of steam from the boiler to a safe and usable level.

There are many benefits to using a pressure reducing station, including:

Increased safety: PRSs help to reduce the risk of steam burns and other accidents by reducing the pressure of steam.

Improved efficiency: PRSs can help to improve the efficiency of steam systems by reducing the amount of energy that is wasted.

Reduced costs: PRSs can help to reduce the cost of operating a steam system by reducing the amount of energy that is consumed.

There are two main types of pressure reducing stations: direct acting and pilot operated. Direct acting PRSs use a spring to regulate the pressure of the steam, while pilot operated PRSs use a small pilot valve to control the main valve.

The size of a pressure reducing station is determined by the following factors:

The inlet pressure of the steam

The outlet pressure of the steam

The flow rate of the steam

The desired accuracy of the pressure reduction

The installation of a pressure reducing station should be done by a qualified professional. The following steps should be followed:

Select a location for the PRS that is accessible and free of obstructions.

Install the PRS according to the manufacturer’s instructions.

Purge the PRS of air and debris.

Turn on the steam supply and test the PRS for leaks.

The maintenance of a pressure reducing station is relatively simple. The following steps should be followed:

Inspect the PRS regularly for leaks and damage.

Replace the filters and gaskets as needed.

Clean the PRS as needed.

The following steps can be used to troubleshoot problems with pressure reducing stations:

Inspect the PRS for leaks.

Check the valves and seals for damage.

Clean the filters.

Reinstall the PRS according to the manufacturer’s instructions

Pressure reducing stations can be purchased from a variety of sources, including:

Industrial supply stores

Online retailers

Boiler manufacturers

The cost of a pressure reducing station will vary depending on the size, type, and manufacturer of the PRS. In general, PRSs can cost anywhere from a few hundred dollars to several thousand dollars.