Pressurised Condensate Recovery Module:

The Pressurised Condensate Recovery module offers energy savings water treatment costs, and it also calculates possible savings.

In this environmentally conscious world we always look forward to securing and reusing the most amount of energy. Returning the maximum amount of condensate back to the boiler will give the highest ROI on investments through reducing maintenance and energy costs.

The pressurized system is also able to provide an impressive increase in Boiler’s efficiency of operation.

Steam is mostly created by the following factors

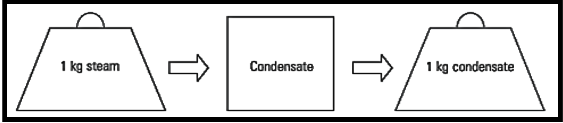

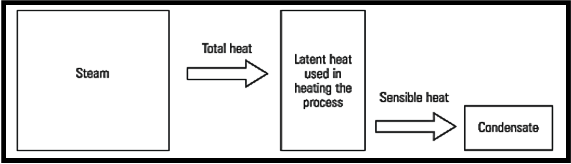

If 1 kg of steam is completely condensed, 1 kg condensate forms at the same temperature and pressure. The steam that is saturated, when it enters the process, loses its heat stored in the latent state that is a significant portion of the heat it holds. The rest of the heat contained in the steam is stored in the condensate and is referred to as sensible heat.

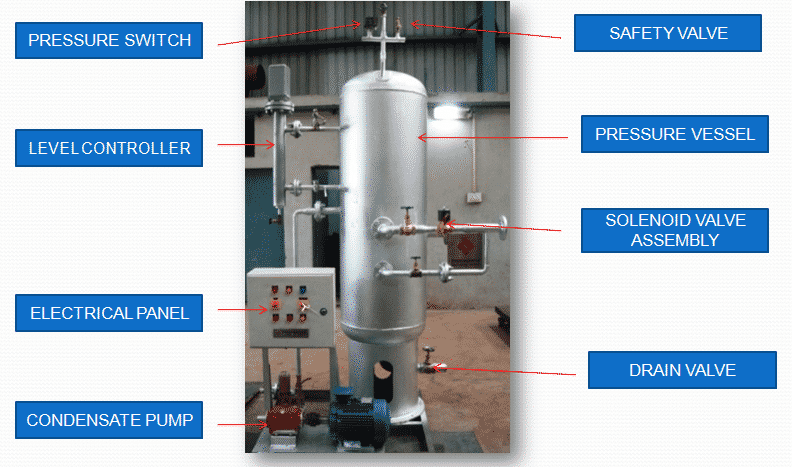

The condensate is now delivered into Boiler Boiler together with the water that comes via the feed pump. As a result, the total temperature of water that is entering to the Boiler shell is much higher than that of the water without condensate recovery. Boiler’s efficiency of operation.

To generate steam the total energy demand of the water is reduced which results in less energy consumption and consequently savings that are compounded each year.

Saturated steam is used for heating to gives up its latent heat, which is a too large proportion of the total heat its contents. The remainder of the heat in the steam is retained in the condensate as sensible heat in fig.

Pressurised Condensate Recovery Module (PCRM) is also a unique system wherein the condensate generated from your process is fed back under pressure directly to the boiler, unlike any other conventional condensate recovery system where the condensate is discharged at atmospheric pressure.

Also by reducing the amount of fresh makeup water entering the Boiler, reduces the amount of water treatment required. Condensate being distilled in quality (almost no TDS) also reduces the Blowdown frequency, again operational cost savings.

It also prevents

Unstable temperature control, Product quality problems, Excessive corrosion of heating surfaces, Water hammer, Noisy operation, Equipment damage.

So, it can be concluded that the Pressurised Condensate Recovery Module is an all-around energy saver with an amazingly short payback period.

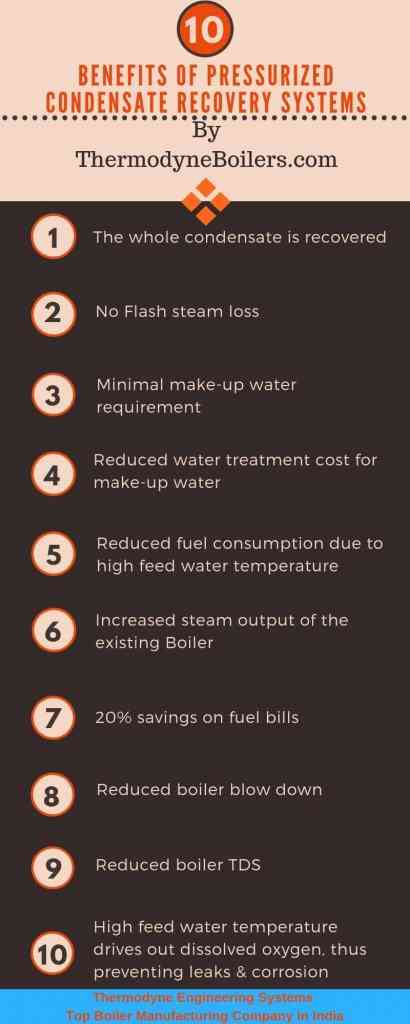

Advantages of PCRM:

Our Pressurised Condensate Recovery Module system serves you the following advantages:

- The whole condensate is recovered

- No Flash steam loss

- Minimal make-up water requirement

- Prevents loss of mass/quantity of condensate

- Reduced water treatment cost for make-up water

- Reduced fuel consumption due to high feed water temperature

- An increased steam output of the existing Boiler

- Excellent Return on investments

PCRM Infographic: 10 Benefits of PCRM

Pressurised Condensate Recovery Module (PCRM) : Introduction & Benefits FAQ

A high pressure condensate return system is a type of condensate recovery system that uses pumps to return condensate from steam users back to the boiler at a higher pressure than the original steam pressure. This allows the condensate to be used directly as feedwater without having to be deaerated, which saves energy.

There are several benefits to using a high pressure condensate return system, including:

Increased energy efficiency: By returning condensate to the boiler at a higher pressure, less energy is needed to heat the boiler feedwater. This can lead to significant savings in energy costs.

Reduced emissions: By reducing the amount of steam that is wasted, high pressure condensate return systems can help to reduce greenhouse gas emissions.

Improved plant reliability: By ensuring that the boiler feedwater is always at the correct temperature and pressure, high pressure condensate return systems can help to improve plant reliability and uptime.

There are two main types of high pressure condensate return systems:

Positive displacement pumps: Positive displacement pumps use a piston or diaphragm to move the condensate from the steam users to the boiler. These pumps are typically used in systems with high condensate flow rates.

Centrifugal pumps: Centrifugal pumps use centrifugal force to move the condensate from the steam users to the boiler. These pumps are typically used in systems with lower condensate flow rates.

When choosing a high pressure condensate return system, there are several factors to consider, including:

The amount of condensate that needs to be recovered

The pressure at which the condensate needs to be returned to the boiler

The type of steam users that are being used

The budget

The installation of a high pressure condensate return system is a complex process that should be done by a qualified professional. The installation process will vary depending on the type of system that is being installed.

High pressure condensate return systems require regular maintenance to ensure that they operate properly. The maintenance schedule will vary depending on the type of system that is being used.

Some common problems with high pressure condensate return systems include:

Clogged condensate lines

Pump cavitation

Leaks

Improper condensate return temperature

If you are experiencing problems with your high pressure condensate return system, there are a few things that you can do to troubleshoot the problem:

Check the condensate lines for clogs

Check the pump for cavitation

Check for leaks

Check the condensate return temperature

There are a number of resources available to learn more about high pressure condensate return systems, including:

Manufacturers’ websites

Trade publications

Technical training courses

The future trends for high pressure condensate return systems include:

Increased demand for energy efficiency

Increased focus on reducing emissions

Increased demand for reliable and uptime-critical systems