Table of Contents

Syphons Coils Prevent Damage to Pressure Gauges in Steam Boiler

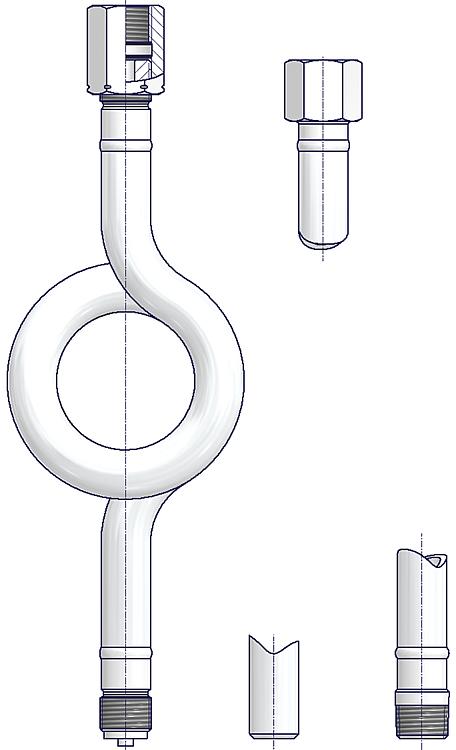

A syphons coil is a type of pressure gauge protection device that is used in boilers. It is a looped or coiled pipe that is placed directly on the piping before the pressure gauge. The siphon coil allows condensate to form and be collected inside the coil, preventing the hot media (hot vapors, not just steam) from coming in direct contact with the pressure instrument. This protects the pressure gauge from damage caused by heat and pressure surges.

The syphon coil is normally used for vertical installations. However, it can also be used for horizontal applications if the loop is designed with a slight dip to allow for the collection of condensate.

The syphon allows condensate to form and be collected inside the syphon, preventing the hot media (hot vapors, not just steam) from coming in direct contact with the pressure instrument

Understanding Steam Boilers and Pressure Gauges

Steam Boilers: Powerhouses of Industrial Processes

Steam boilers are a fundamental part of various industrial processes, serving as powerhouses that produce steam, which can be used for heating, power generation, and other applications. The process of steam generation involves heating water in a confined space until it reaches its boiling point, producing steam that can be harnessed for energy transfer.

Pressure Gauges: Monitoring Boiler Pressure

Pressure gauges are indispensable instruments in Industrial steam boilers as they provide real-time information about the pressure inside the system. Monitoring boiler pressure is crucial to ensure safe and efficient operation. If the pressure becomes too high, it can lead to potential hazards, such as boiler explosions. On the other hand, low pressure can affect the overall performance of the system.

.

The Challenges of High-Temperature and High-Pressure Environment

Adverse Effects on Pressure Gauges

The harsh conditions inside a steam boiler can pose significant challenges for pressure gauges. The combination of high temperatures and pressures can cause the gauge’s sensitive components to malfunction or even fail, leading to inaccurate readings. Moreover, direct exposure to high-temperature steam can lead to corrosion and physical damage, compromising the gauge’s integrity.

The Role of Syphons Coils

To mitigate the adverse effects of the steam boiler environment on pressure gauges, engineers and manufacturers have introduced a smart solution – siphon coils. A siphon coil is a U-shaped pipe made of heat-resistant materials, such as stainless steel or other alloys, designed to protect the pressure gauge from direct exposure to the high-temperature steam.

How Syphon Coils Work

Principle of Operation

Siphon coils work on a simple yet effective principle. The U-shaped coil is filled with a liquid, typically water or oil. As steam enters the coil, it passes through the liquid-filled U-shape, condensing the steam. This condensed steam, in the form of water or oil, acts as a barrier between the live steam and the pressure gauge.

Preventing Direct Steam Exposure

By creating a protective barrier, siphon coils prevent the direct contact of high-temperature steam with the pressure gauge. This not only protects the sensitive components of the gauge but also ensures that the gauge provides accurate readings. The condensed liquid acts as a buffer, absorbing the heat energy from the steam and reducing its temperature before it reaches the gauge.

Equalizing Pressure for Accuracy

Another essential function of siphon coils is to equalize the pressure between the steam inside the boiler and the pressure gauge. Steam within the coil will reach the same pressure as inside the boiler, allowing the gauge to accurately measure the system’s pressure.

Advantages of Siphon Coils

Enhanced Safety

Siphon coils significantly enhance the safety of steam boiler operations. By preventing direct steam exposure to the pressure gauge, the risk of gauge failure or inaccurate readings due to high-temperature steam is minimized. This, in turn, helps prevent potential accidents or equipment damage.

Extended Gauge Lifespan

The use of siphon coils can substantially extend the lifespan of pressure gauges. By protecting the gauge from the harsh boiler environment, the gauge’s components remain intact, ensuring long-term reliability and performance.

Reduced Maintenance Costs

As pressure gauges equipped with siphon coils are less prone to damage, the frequency of gauge replacements or repairs is reduced. This translates to lower maintenance costs and improved overall efficiency in industrial operations.

Accurate Readings for Better Control

Accurate pressure readings are essential for maintaining optimal boiler performance. With siphon coils in place, pressure gauges can provide reliable and precise measurements, enabling operators to make well-informed decisions and adjustments to the boiler’s operation.

In conclusion, steam boilers are crucial assets in various industrial processes, and pressure gauges play a pivotal role in ensuring their safe and efficient operation. However, the high-temperature and high-pressure environment within steam boilers can pose significant challenges to the integrity and accuracy of pressure gauges. Siphon coils offer a practical solution to prevent damage to pressure gauges by creating a protective barrier between the live steam and the gauge, allowing for accurate readings and enhanced safety.

When incorporating siphon coils into steam boiler systems, industrial operators can benefit from extended gauge lifespans, reduced maintenance costs, and better control over the boiler’s performance. By embracing this smart technology, businesses can optimize their operations, increase safety, and leave other competitors behind, securing a prominent position in the market.

Remember, ensuring the reliability and safety of steam boiler systems is vital for a successful and thriving industrial enterprise. With siphon coils, businesses can take a proactive approach to protect their pressure gauges and ensure the seamless operation of their steam boilers.

What is a Siphons Coil?

A siphons coil, also known as a siphon coil, is a complex device used in various industries to transfer and manipulate liquids or gases. Its design consists of a coiled tube, typically made of copper or stainless steel, that facilitates the efficient transfer of fluids. This technology harnesses the principles of fluid dynamics and offers remarkable advantages in multiple fields.

Understanding the Working Mechanism

The syphons coil operates based on the principles of pressure differentials and fluid flow. When fluid enters the coil, it encounters resistance due to the coiled structure, causing a decrease in pressure. As a result, the fluid flows from regions of higher pressure to lower pressure, allowing for controlled movement and distribution.

Applications Across Industries

1. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely on syphons coils to regulate temperature and ensure optimal air circulation. By effectively transferring heat or cold, these coils contribute to energy efficiency and comfort in residential, commercial, and industrial settings.

2. Brewing and Distilling

In the brewing and distilling industry, syphons coils play a crucial role in the cooling and condensing processes. By efficiently transferring heat away from the mixture, they enable precise control over fermentation and distillation, leading to the production of high-quality beverages.

3. Chemical Processing

Syphons coils find extensive use in chemical processing plants. They facilitate the transportation of corrosive liquids, enable heat exchange in chemical reactors, and enhance the efficiency of various chemical reactions. Their robust design and compatibility with different substances make them invaluable assets in this industry.

4. Renewable Energy

The renewable energy sector, including solar and geothermal power, benefits from syphons coils’ heat transfer capabilities. By efficiently collecting and distributing thermal energy, these coils enhance the overall efficiency of renewable energy systems, contributing to a greener and more sustainable future.

Advantages of Siphons Coil Technology

1. Enhanced Heat Transfer

The intricate design of syphons coils maximizes the contact surface area between the fluid and the coil. This results in superior heat transfer efficiency, reducing energy consumption and optimizing system performance.

2. Improved System Durability

Syphons coils are built to withstand high temperatures, pressures, and corrosive substances. Their robust construction ensures longevity, reducing maintenance costs and providing reliable operation in demanding environments.

3. Precise Temperature Control

By facilitating the precise regulation of fluid temperature, syphons coils allow for consistent and accurate control in various processes. This feature is especially critical in industries where temperature plays a vital role in the final product quality.

4. Versatility and Customization

Syphons coils are available in a range of sizes, configurations, and materials, making them adaptable to specific industry requirements. Manufacturers can customize these coils to suit diverse applications, ensuring optimal performance and efficiency.

Unleashing the Potential: How Syphons Coils Drive Success

The adoption of syphons coil technology offers numerous advantages, empowering businesses to achieve new heights of success. By incorporating these coils into their operations, companies can experience:

1. Increased Efficiency and Cost Savings

With enhanced heat transfer and precise temperature control, businesses can optimize their energy consumption and reduce operational costs. Syphons coils enable improved process efficiency, leading to higher productivity and profitability.

2. Enhanced Product Quality

Industries that rely on precise temperature control, such as brewing, distilling, and chemical processing, can greatly benefit from syphons coils. The ability to maintain consistent and accurate temperatures ensures superior product quality, customer satisfaction, and brand reputation.

3. Eco-Friendliness and Sustainability

As the world shifts toward sustainable practices, syphons coils play a significant role in promoting environmental responsibility. By enabling energy-efficient operations and minimizing waste, businesses can contribute to a greener future while complying with stringent environmental regulations.

4. Competitive Advantage

By leveraging the advanced capabilities of syphons coil technology, companies gain a competitive edge in their respective industries. These coils enable process optimization, product innovation, and improved customer experiences, positioning businesses as leaders in their markets.

As we conclude our exploration of syphons coil technology, it becomes evident that their impact is far-reaching and transformative across various industries. From HVAC systems and chemical processing to renewable energy and beyond, the applications and advantages of these coils are undeniable. By embracing the potential of syphons coils, businesses can drive success, optimize operations, and shape a future defined by innovation and sustainability.

Syphons Coils Prevent Damage to Pressure Gauges in Steam Boilers FAQ

A boiler syphon is a device that is used to protect steam pressure gauges from damage. It does this by creating a vacuum that prevents steam from entering the gauge.

A Steam boiler syphon consists of two pipes. One pipe is connected to the steam supply, and the other pipe is connected to the drain. When steam enters the siphon, it creates a vacuum that draws water from the drain pipe into the steam pipe. This water then acts as a barrier between the steam and the gauge.

Industrial Boiler syphons offer a number of benefits, including:

Protection of steam pressure gauges from damage

Increased safety

Reduced maintenance costs

Increased efficiency

Industrial Steam Boilers syphons have a few disadvantages, including:

Increased cost

Potential for leaks

Increased complexity

There are two main types of boilers syphons:

Coil type syphons: These siphons have a coil of pipe that is designed to create a vacuum.

Straight type syphons: These syphons have a straight pipe that is designed to create a vacuum.

The lifespan of a boiler syphons will vary depending on the quality of the siphon and the operating conditions. However, most boiler siphons will last for several years.

Boiler syphons should be inspected at least once a year. This inspection should include checking for leaks, damage, and buildup of sediment.

If you are experiencing problems with your boiler siphon, there are a few things you can do to troubleshoot the problem:

Check for leaks.

Check for damage.

Check for buildup of sediment.

Make sure that the siphon is properly installed

To replace a boiler syphons, you will need to:

Disconnect the old syphons from the steam supply and the drain.

Install the new siphon.

Reconnect the old syphon to the steam supply and the drain.

Buy Boiler Spare Parts at the Best Price

Thermodyne Boilers supplies 100+ Industrial Boiler Parts all over India. Contact our sales team & send your requirement to get prices & discounts