Table of Contents

Boilers Steam Trap Assembly:

A steam trap assembly is an essential element of a steam distribution piping system. As steam flows through a pipe, Steam Trap Assemblies cool off due to heat losses and converts into hot water; this hot water is called condensate.

The function of a steam trap is to release condensate as soon as it is formed and to prevent the discharge of steam so that only steam remains in the system.

In addition to condensate removal, a steam trap also performs air venting function, thereby increasing the thermal efficiency and reliability of the Steam Distribution System.

Thermodyne provide pre-fabricated steam trap assemblies for process piping and help you install the precise size of steam traps according to the process and steam requirement.

Steam Trap Assembly : Principle Working

Steam traps work on various principles depending on its type:

-

Density operated Steam Traps

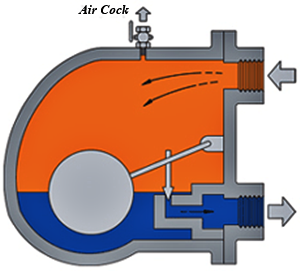

When the separation of water or condensate from steam is carried out using the gravity separation principle are termed as the density operated steam traps. In this type, condensate which has a high density gets settled at the bottom and steam being lighter is at the top. This is the most efficient method of separation as this is a mechanical separation method.

-

Kinetic Energy operated steam traps

These type of valves work on the Bernoulli’s principle. These valves use variation in pressure and velocity of steam for the separation process. Due to high pressure and velocity variation water hammering may also occur which can damage the valve.

Importance of sizing steam traps

It is very important to select the right size of steam traps because if we install the undersize valve than the required, the amount of separation of condensate from steam may decrease which will further affect the steam purity and on the other hand if an oversize steam trap valve is installed in a steam line, steam losses or heat losses may increase significantly thereby affecting the Boiler Efficiency.

Contact our experienced engineers for the right-sizing of the steam traps in a steam pipeline of your process.

Boiler Steam Trap Assembly FAQ

A steam trap is an automatic valve that allows condensate to drain from a steam system while preventing steam from escaping.

There are three main types of steam traps: mechanical, thermostatic, and thermodynamic. Mechanical traps are the most common type and work by using a float to open and close the valve. Thermostatic traps use a bimetallic coil to open and close the valve, and thermodynamic traps use the difference in temperature between steam and condensate to open and close the valve.

Steam traps work by using a combination of physical and thermal properties to differentiate between steam and condensate. When steam enters the trap, it is hotter than the condensate. This difference in temperature causes the steam to expand and rise to the top of the trap. The condensate, on the other hand, is cooler and denser, so it sinks to the bottom of the trap. The trap is designed to allow the condensate to drain out while preventing the steam from escaping.

Steam traps are used in a variety of applications, including heating, ventilating, and air conditioning (HVAC) systems, industrial processes, and power plants.

Steam traps should be maintained on a regular basis to ensure that they are working properly. This includes inspecting the trap for leaks, cleaning the trap, and lubricating the moving parts.

There are a few signs that a steam trap may be malfunctioning. These include:

Steam leaking from the trap

Condensate not draining from the trap

The trap making noise

The trap being hot to the touch

A malfunctioning steam trap can have a number of negative consequences, including:

Loss of steam

Reduced efficiency

Increased operating costs

Damage to equipment

There are a few things you can do to prevent steam trap problems, including:

Installing the correct type of trap for the application

Maintaining the trap on a regular basis

Using high-quality traps

Training employees on how to operate and maintain steam traps

If you are experiencing problems with a steam trap, there are a few things you can do to troubleshoot the problem, including:

Visually inspect the trap for leaks, damage, or obstructions

Check the trap’s operation by running steam through it

Lubricate the trap’s moving parts

Replace the trap if it is malfunctioning

There are a number of resources available to learn more about steam traps. These include:

Manufacturers’ websites

Trade magazines

Online forums

Technical training courses