Thermodyne Product Range

Thermodyne Engineering Systems have many products to serve steam processing & power industry, such as Industrial Steam Boilers, Steam Generators & Accessories like chimney.

For Product Inquiry > Contact our Sales Team

Packaged Boilers: Intech

Intech Boiler-3 passes Internal Furnace Packaged Type Boiler- is the conventional three pass smoke-tube design wood fired steam boiler.

Capacity: 0.3-6TPH Fuel: Solid Fuel ( Coal, Wood etc.)

Pressure: Up to 25 Kg/cm2 Ideal Industries: Sugar, Dairy etc.

Top Feed Husk Fired Boiler:

Intech Top Feed Boiler- Internal Furnace Packaged Type Husk Fired Boiler– is said so because of their unique automatic fuel feeding from the top of the Internal Furnace Boiler.

Capacity: 0.3-6TPH Fuel: Rice Husk

Pressure: Up to 25 Kg/cm2 Ideal Industries: Sugar, Dairy etc.

Oil / Gas Fired Boilers : Savemax

Savemax Boiler– Savemax Boiler is the conventional three pass smoke-tube design Oil / Gas fired steam boiler having an internal water cooling furnace area. The superior and features make it the ideal boiler.

Capacity: .5TPH-10 TPH Fuel: Liquid & Gas Fuels

Pressure: Up to 25 Kg/cm2 Ideal Industries: Sugar, Dairy etc

Smoke Cum Water Tube Boiler: Combitherm

(Combination Boiler)

Combitherm Boiler– Combitherm boiler or is known among others as Combi boiler is a unique water cum smoke tube type design. It is the combination of both Water Tube Boiler and Smoke Tube Boiler.

Capacity: 1-15TPH Fuel: Solid Fuel ( Coal, Wood etc.)

Pressure: Up to 25 Kg/cm2 Ideal Industries: Sugar, Dairy etc.

Combitherm ultra boilers

Combitherm – Ultra boiler (CTM-Ultra) is factory assembled unit, installed on a skid base frame requiring minimum site.

Capacity: 1 TPH -25 TPH Fuel: Solid Fuel ( Coal, Wood etc.)

Pressure: Up to 25 Kg/cm2 Ideal Industries: Sugar, Dairy etc.

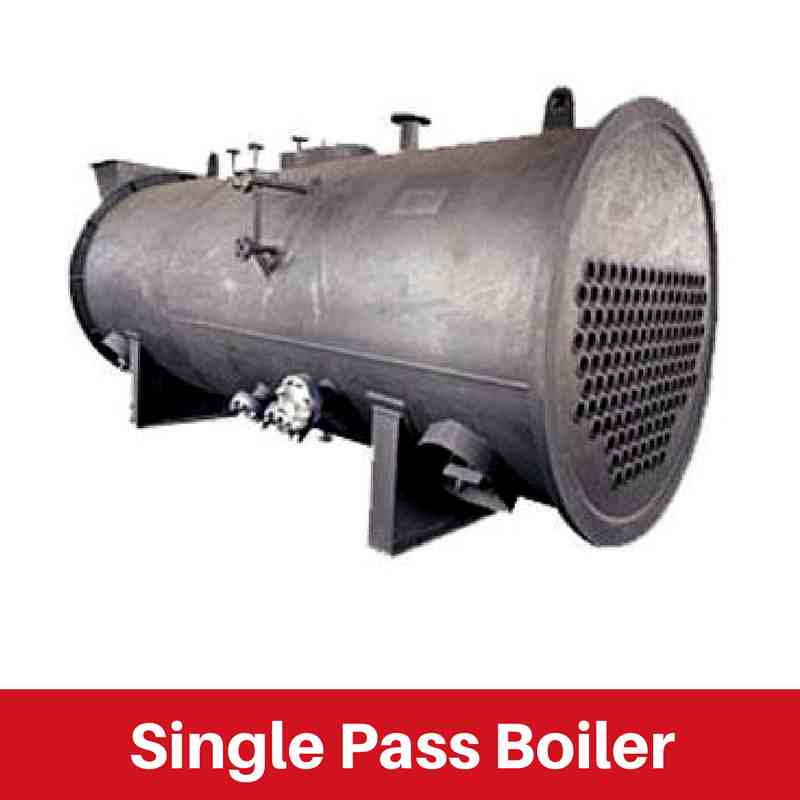

Single Pass Boiler with external furnace: Agromax

Agromax – The Single Pass Boilers With External Furnace is multiple solid fuels

Capacity: 1 TPH -4 TPH Fuel: Solid Fuel ( Coal, Wood etc.)

Pressure: Up to 17.5 Kg/cm2 Ideal Industries: Sugar, Dairy etc.

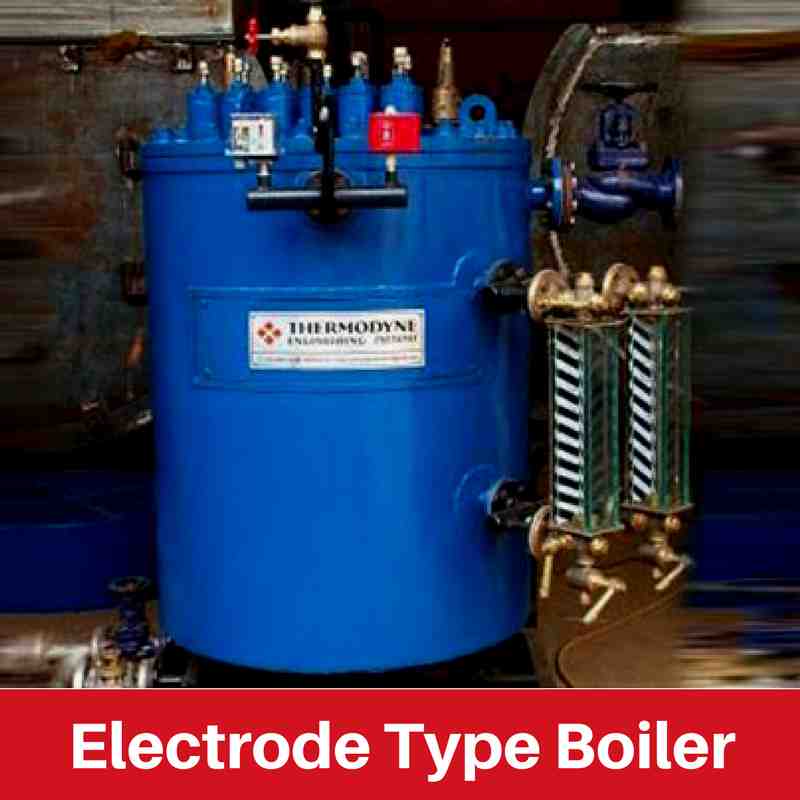

Electrode type Boilers: Electra

Operating Principle:- ELECTRA – Electrode Type Boiler differs in the principle from any other method of heating water

Capacity: 50KPH -1500KPH Fuel: Electricity

Pressure: Up to 25 Kg/cm2 Ideal Industries: Sugar, Dairy etc.

Water Tube Coil Type Boiler: Revosteam

REVOSTEAM is the conventional forced circulation type water tube coil type boiler incorporating the industry.

Capacity: 100KPH -1200KPH Fuel: Liquid/Gas Fired Fuels

Pressure: Up to 25 Kg/cm2 Ideal Industries: Sugar, Dairy etc.

Hot Water Generator: Instatherm

Instatherm is the efficient and cost-effective way to generate hot water instantly. Instatherm is a packaged type…

Capacity: 25,000 Kcal/hr – 2500000 Kcal/hr Fuel: Solid,Liquid & Gasious Fuels

Ideal Industries: Sugar, Dairy etc.

Waste Heat Recovery Boiler: Wastetherm

Fuel is money. The more fuel we burn in a boiler, the more money is spent

Capacity: 100KPH -10TPH Fuel: Waste Heat

Pressure: Up to 25 Kg/cm2 Ideal Industries: Sugar, Dairy etc.

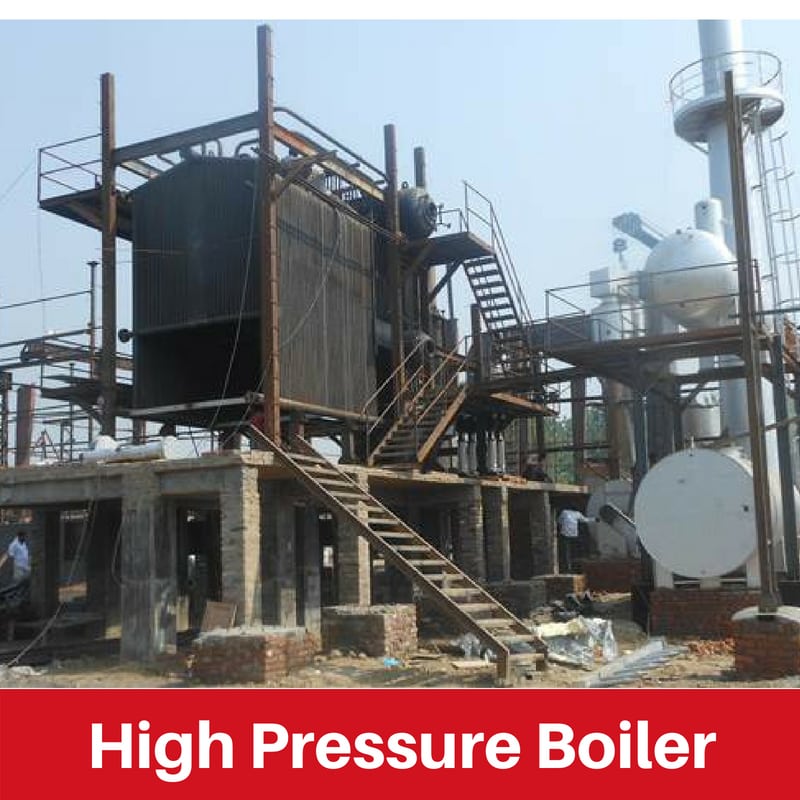

High Pressure Boilers: Powertherm

High Pressure Boilers are entirely water tube design boilers for high-pressure steam desires.

Capacity: 6TPH -30TPH Fuel: Solid, Liquid & Gaseous Fuels

Pressure: Up to 40 Kg/cm2 Ideal Industries: Sugar, Dairy etc.

Hot Air Generators: Thermair

Thermair, hot air generators consist of a shell and tube type heat exchanger which is duly insulated to prevent radiation losses.

Capacity:25,000 Kcal/hr – 2500000 Kcal/hr Fuel: Solid, Liquid & Gaseous Fuels

Ideal Industries: Sugar, Dairy etc.

Thermic Fluid Heater: Fluidtherm

Fluidtherm is one of the most trusted names among Thermic Fluid Heaters and is synonymous with high reliability, high efficiency

Capacity:25,000 Kcal/hr – 3000000 Kcal/hr Fuel: Solid, Liquid & Gaseous Fuels

Ideal Industries: Sugar, Dairy etc.

Pressurised Condensate Recovery Module

Let’s introduce the Condensate Recovery System. It includes energy costing, water charges and water

Industrial Fans & Blowers

Specially designed, high-efficiency fans are offered for all boiler applications

Pressure Vessels and Accumulators

Thermodyne Boilers provide steam accumulators to meet the unique demands of fluctuating steam loads in plants

Industrial Chimneys

Industrial Chimney is a device for Exiting hot flue gases or smoke from a Steam boiler, stove, furnace or fireplace to the outside atmosphere…

Process Tanks

High Pressure Boilers are entirely water tube design boilers for high-pressure steam desires.

Steam Pressure Reducing Stations

Thermodyne Engineering Systems provide Steam pressure reducing stations (PRS) for process application

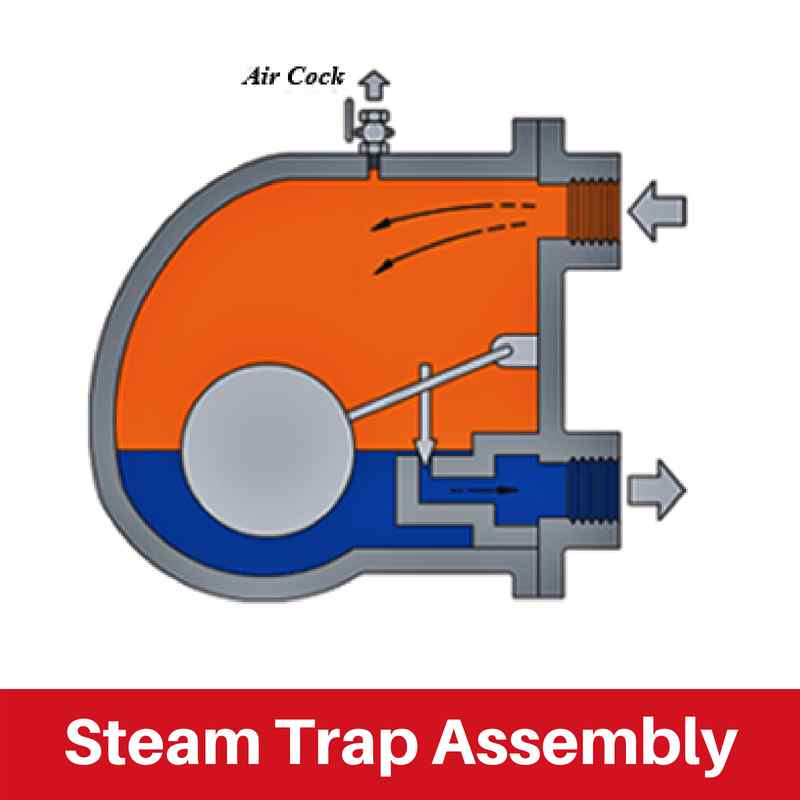

Steam Trap Assemblies

A steam trap is an essential element of a steam distribution piping system. As steam flows through a pipe, it cools off due to heat.

Deaerator Tanks

Thermodyne Boilers manufactures Deaerator tanks that suit the customer needs.

Air Preheater(APH)

Thermodyne Boilers manufacture Air Preheater that suit the customer needs for increasing the boiler efficiency.

Wet Scrubber

Wet Scrubbers are the pollution control devices usually installed in the path of the flue gases to extract Sulfur compounds or oxides of sulfur such as Sulfur Dioxide (SO2) and Ash particles.

Thermodyne Products Range of Boilers FAQ

1. What are Thermodyne boilers?

Thermodyne boilers are a type of industrial boiler that is used to generate steam. They are made by Thermodyne Engineering Systems, a company that has been manufacturing boilers for over 23 years.

2. What are the benefits of using Thermodyne boilers?

Thermodyne boilers offer a number of benefits, including:

High efficiency: Thermodyne boilers are highly efficient, which can save you money on your energy bills.

Long lifespan: Thermodyne boilers are built to last, with a lifespan of up to 23 years.

Easy maintenance: Thermodyne boilers are easy to maintain, which can save you money on service calls.

3. What are the different types of Thermodyne boilers?

Thermodyne boilers come in a variety of types, including:

Firetube boilers: Firetube boilers are the most common type of boiler. They work by passing hot water or steam through tubes that are surrounded by a fire.

Watertube boilers: Watertube boilers are less common than firetube boilers. They work by passing hot water or steam through tubes that are surrounded by water.

Packaged boilers: Packaged boilers are pre-assembled boilers that are ready to be installed. They are a good option for businesses that need a boiler that is easy to install and maintain.

4. How do I choose the right Thermodyne boiler for my needs?

When choosing a Thermodyne boiler, you need to consider the following factors:

The size of your business: The size of your business will determine the size of the boiler that you need.

The type of fuel that you use: Thermodyne boilers can be fueled by natural gas, propane, or oil.

The number of hours that you need the boiler to operate: If you need the boiler to operate for long periods of time, you will need a boiler that is designed for continuous operation.

5. Where can I buy a Thermodyne boiler?

Thermodyne boilers are available from a variety of dealers, including Thermodyne Engineering Systems.

6. How much does a Thermodyne boiler cost?

The cost of a Thermodyne boiler varies depending on the size, type, and fuel type of the boiler.

7. How do I maintain my Thermodyne boiler?

Your Thermodyne boiler should be maintained on a regular basis by a qualified technician. This will help to ensure that your boiler operates efficiently and safely.

8. What are the safety features of Thermodyne boilers?

Thermodyne boilers have a number of safety features, including:

A pressure relief valve: The pressure relief valve releases steam or water if the pressure inside the boiler gets too high.

A low water cutoff: The low water cutoff shuts down the boiler if the water level gets too low.

A flame rollout switch: The flame rollout switch shuts down the boiler if the flame goes out.

9. What are the warranty terms for Thermodyne boilers?

Thermodyne boilers come with a one-year warranty on parts and labor.

10.How do I contact Thermodyne Engineering System

You can contact Thermodyne Engineering Systems by phone, email, or through their website.