Table of Contents

Packaged Boiler

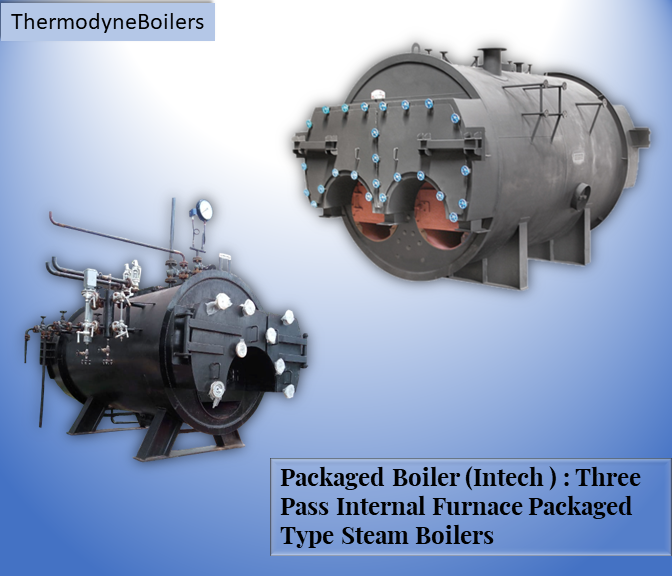

The Intech boiler, as its name suggests, is a packaged boiler with a 3-pass internal furnace Packaged boiler. It is a conventional 3 smoke-tube design approach and is intended for burning coal and wood within an internal furnace. As a result, it is often referred to as a steam boiler for coal/wood combustion therefore sometimes known as coal/wood fired Steam Boiler.

The Packaged Boiler is offered in three options: dry back, semi-wet back, and fully wet-back. It is particularly well-suited for manually burning solid fuels such as coal, wood, or briquettes.

The furnace of the boiler is completely immersed in water, facilitating the efficient transfer of maximum heat from the furnace to the surrounding water. Grate bars, upon which the fuel is combusted, are positioned within the furnace to ensure the optimal grate area for effective fuel burning.

Also Read: Dry Bottom Boiler

The fuel of Packaged Type Boiler is fired on the grate and flue gases are released on combustion of fuel. The flue gases then travel from the furnace to the flue gas outlet through the Second and Third Pass Smoke Tubes, reversing from smoke boxes on their way out.

Flue gases traveling at high speed ensures maximum convective heat transfer rate and 3 passes (2 tube passes and 1 furnace pass) extract the maximum amount of heat from the gases.

An induced draft fan is provided in the Boiler Assembly, for proper combustion and maintaining draft in the furnace. This conventional design also ensures effective distribution of thermal and mechanical stresses in the heating equipment thereby increasing the boiler life.

Water pre-heater or Economiser may be provided in a shell and tube design to increase the efficiency of a boiler. This implies recovering waste heat from flue gases by reducing the exhaust temperature leaving the boiler.

Packaged Boilers Types

There are two types of packaged boilers ( Intech Models)

Packaged Boilers Advantages

- The expansive convective heating surface area in the 2nd and 3rd pass tubes guarantees optimal heat transfer.

- Large water and steam holding space prove invaluable in managing varying steam requirements essential for the process.

- The elevated dryness fraction of the steam enhances its usable heat content.

- The production of dry steam reduces processing duration, conserves steam, and enhances the quality of processed goods.

- Horizontally Packaged Boiler – less site work required, quick commissioning and hinged doors are provided, for easy inspection & maintenance of boiler.

Packaged Boiler (Intech) Capacity

Intech Model – Three Pass Internal Furnace Packaged Type Boiler is available in capacities:

| Model | Capacity | Fuel |

| Intech – Packaged Boiler | 0.3 TPH to 4 TPH | Wood, Coal, Briquettes |

Also Read: Husk Fired Boiler: Internal Furnace Top Feed Steam Boilers

Packaged Boiler’s Features and Advantages

S.No. |

Features |

Advantage |

Benefits |

| 1. |

Skid mounted | No special foundation required |

Space and cost saving |

| 2. |

No external furnace |

Brickwork is not required |

Cost and time saving |

| 3. |

Internal furnace |

Lesser heat losses |

Early paybacks |

| 4. |

Compact |

High efficiency |

Low operating cost |

| 5. |

Rigid |

Low maintenance |

Long life |

Internal Furnace Packaged Boilers: Video

If You search more boiler related videos click here

Packaged Steam Boilers for Sale:

We, Thermodyne Engineering Systems, are trusted packaged boilers manufacturers & packaged boilers, suppliers. If We provide the best price for all steam processing industries.

Please Contact us for best boilers quotes > here

Other Steam Boilers Products Manufactured by Thermodyne Boilers

Boiler Application Use For Boiler Solutions

- Boiler Losses That Eat Away Your Profits

- Dissolved Gases in Feed Water and Its Effect

- Pressure Reduction System

- How to minimize the Blowdown Losses

- PACKAGED BOILER( INTECH ) : Three Pass Internal Furnace Packaged Boiler

Three Pass Internal Furnace Packaged Packaged Boiler (Intech ) FAQ

A packaged steam boiler is a complete heating system that is factory-assembled and delivered to the job site ready to be installed. Packaged boilers are available in a variety of sizes and types, and can be powered by natural gas, propane, oil, or electricity.

Packaged steam boilers offer a number of benefits, including:

Compact size: Packaged boilers are typically much smaller than traditional boiler systems, making them ideal for installation in tight spaces.

Efficiency: Packaged boilers are highly efficient, meaning they can save you money on your energy bills.

Ease of installation: Packaged boilers are designed to be easy to install, which can save you time and money.

Long-lasting: Packaged boilers are built to last, so you can be confident that your investment will be protected.

There are two main types of packaged steam boilers: fire-tube boilers and water-tube boilers.

Fire-tube boilers: Fire-tube boilers have a firebox that is surrounded by water tubes. The fire heats the water tubes, which then transfer heat to the surrounding water.

Water-tube boilers: Water-tube boilers have a series of water tubes that are surrounded by a firebox. The fire heats the water tubes, which then produce steam.

Packaged steam boilers can be powered by a variety of fuels, including:

Natural gas: Natural gas is the most common fuel for packaged steam boilers. It is a clean-burning fuel that is relatively inexpensive.

Propane: Propane is another popular fuel for packaged steam boilers. It is a clean-burning fuel that is available in many areas.

Oil: Oil is a less common fuel for packaged steam boilers. It is a more expensive fuel than natural gas or propane, but it is still a viable option for some applications.

Electricity: Electric boilers are the least common type of packaged steam boiler. They are more expensive to operate than boilers that are powered by other fuels, but they do not require any fuel storage.

Packaged steam boilers are available in a variety of sizes. The size of the boiler that you need will depend on the amount of steam that you need to produce.

The cost of a packaged steam boiler will vary depending on the size, type, and fuel of the boiler. Boilers that are powered by natural gas or propane are typically less expensive than boilers that are powered by oil or electricity.

Packaged steam boilers can last for many years with proper maintenance. The average lifespan of a packaged steam boiler is 23 years.

The most common maintenance tasks for a packaged steam boiler include:

Inspecting the boiler for leaks: Leaks can cause damage to the boiler and the surrounding area.

Cleaning the boiler: Cleaning the boiler removes dirt and debris that can build up and cause problems.

Checking the boiler’s water level: The water level in the boiler should be checked regularly and topped off as needed.

Testing the boiler’s safety devices: The safety devices on the boiler should be tested regularly to make sure that they are working properly.

You can find a qualified installer for a packaged steam boiler by contacting a local plumbing or heating contractor. The contractor should be familiar with the type of boiler that you want to install and should be able to provide you with a quote for the installation.

The government regulates packaged steam boilers in order to ensure safety. The regulations vary from state to state, so it is important to check with your local government to find out what the requirements are.