Table of Contents

Overload Relays Principle

The principle of an overload relay in a boiler is to provide protection against excessive electrical current and prevent damage to the electrical components, particularly the motor driving the boiler’s critical systems, such as pumps, fans, or other mechanical equipment.

In a boiler system, various electrical motors are used to operate essential components like feedwater pumps, combustion air fans, and draft fans. These motors draw electrical current to perform their functions. However, during certain abnormal situations, such as mechanical failure, blocked pipelines, or excessive load demand, the motor can draw more current than it is designed to handle. This can lead to overheating and, in severe cases, motor burnout or damage.

Overload Relays: An Essential Safety Device for Industrial Steam Boilers

An overload relay is a safety device that protects the motor and other electrical components in a steam boiler from overheating and damage. It does this by monitoring the current flowing through the motor and tripping the circuit if the current exceeds a preset value.

Overload relays typically use one of two methods to monitor current:

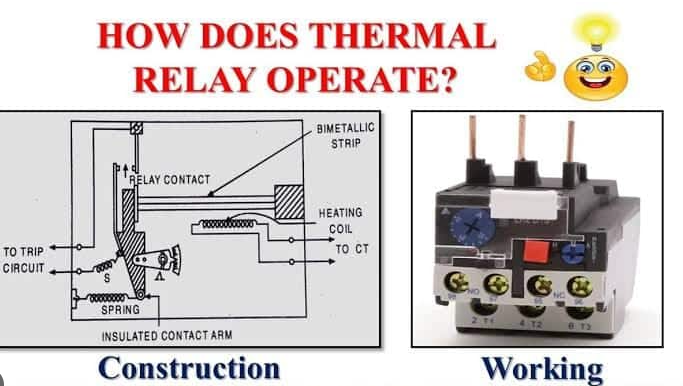

- Thermal overload relays use a bimetallic strip that bends when the current flowing through it exceeds a certain value. This bending opens the contacts of the overload relay, disconnecting the motor from the power supply.

- Magnetic overload relays use a solenoid that is energized when the current flowing through it exceeds a certain value. This energizing pulls in a plunger that opens the contacts of the overload relay, disconnecting the motor from the power supply.

Importance of Overload Relays for Steam Boilers

Steam boilers are critical components in numerous industries, including power generation, manufacturing, and heating systems. They are responsible for generating steam by heating water, which is then used for various purposes. However, steam boilers operate under high temperatures and pressures, making them susceptible to potential hazards and failures.

Ensuring Equipment Safety In Steam Boiler

By incorporating overload relays into steam boiler systems, equipment safety can be significantly enhanced. Overload relays act as a preventive measure, ensuring that motors and associated equipment do not experience excessive current levels. This helps in mitigating the risk of electrical faults, motor burnouts, and potential accidents caused by overheating or system failures.

Protecting Against Motor Failures in Industrial boiler

Motors play a vital role in steam Industrial boiler systems, driving essential components such as pumps, fans, and valves. Motor failures can disrupt the entire operation, leading to costly downtime and repairs. Overload relays provide an additional layer of protection for motors by preventing overloads and excessive current flow. By detecting abnormal conditions promptly, they help extend motor lifespan, reduce maintenance costs, and enhance overall system reliability.

Enhancing System Efficiency

Efficiency is a crucial factor in steam boiler operations. Overloaded motors not only consume excessive energy but also result in decreased system efficiency. Overload relays ensure that motors operate within their designed capacity, promoting energy efficiency and preventing unnecessary power consumption. By optimizing motor performance, overload relays contribute to cost savings and sustainable operation of steam boiler systems.

Understanding Overload Relays

What is an Overload Relay?

An overload relay is an electrical device designed to protect motors, generators, and other electrical equipment from overcurrent conditions. It monitors the current flow within a circuit and activates a protective mechanism when the current exceeds a predetermined threshold. By quickly detecting and responding to excessive current levels, overload relays prevent overheating and potential damage to the equipment.

The Importance of Overload Relays

Overload relays serve as a critical safety measure to safeguard electrical systems and equipment. They prevent the motor or device from drawing excessive current for an extended period, which can lead to overheating and, ultimately, system failure. By interrupting the circuit when an overload occurs, these relays protect not only the equipment but also the personnel working in close proximity to it. Furthermore, overload relays help to optimize energy consumption, prolong equipment lifespan, and minimize downtime due to unexpected failures.

Types of Overload Relays

- Thermal Overload Relays: These relays operate based on the principle of thermal expansion. They consist of a heating element that measures the current passing through it. When the current exceeds the predetermined limit, the heating element expands, activating the protective mechanism.

- Electronic Overload Relays: Utilizing advanced electronic components, these relays offer enhanced accuracy and flexibility in protecting electrical systems. They monitor various parameters such as voltage, current, and temperature to detect abnormal conditions and trigger the necessary protective measures.

- Magnetic Overload Relays: Magnetic overload relays utilize the magnetic force generated by the current passing through a coil to activate the protective mechanism. They are commonly used in applications where high starting currents are expected, such as in motor starting circuits.

Overload Relays connection

Connection: The specific connection method for overload relays may vary depending on the type and the manufacturer’s design. However, in general, overload relays are connected in series with the motor they are protecting. Here are the typical steps for connecting an overload relay:

- Identification: Identify the three main motor terminals: T1, T2, and T3. These are the power supply terminals to the motor.

- Disconnect Power: Ensure that the power supply to the motor is disconnected before making any connections.

- Overload Relay Connections: Connect one terminal of the overload relay to the T1 terminal and the other terminal of the overload relay to the T3 terminal.

- Normally Closed (NC) Contacts: The overload relay will have one or more sets of contacts. Typically, these contacts are labeled as NC (Normally Closed). Connect these contacts in series with the control circuit of the motor starter or contactor.

- Power Supply Connections: Reconnect the power supply to the motor, ensuring that the entire motor current passes through the overload relay.

- Adjustment: Depending on the type of overload relay, you may need to adjust the trip current setting to match the motor’s rated current.

Factors to Consider When Selecting an Overload Relay

Choosing the right overload relay for your specific application requires careful consideration of several factors. Here are some key aspects to keep in mind:

Current Rating and Adjustment Range

The overload relay’s current rating should match the motor’s full load current to provide accurate protection. Additionally, ensure that the relay offers an adjustment range suitable for the expected variations in motor load.

Trip Class

Trip class refers to the relay’s response time to overload conditions. It is categorized into classes, such as Class 5, Class 10, and Class 20, each indicating the percentage of motor full load current at which the relay will trip within a specific time frame. Understanding the trip class requirements of your equipment is essential for optimal protection.

Ambient Conditions

Consider the environmental conditions in which the overload relay will operate. Factors such as temperature, humidity, and vibration can impact the relay’s performance and longevity. Select a relay that is suitable for the specific ambient conditions of your application.

Motor Type

Different types of motors have varying characteristics, including their starting current and operating conditions. Ensure that the overload relay is compatible with the motor type to provide effective protection.

Installation and Maintenance Guidelines

To ensure the reliable performance of overload relays, proper installation and regular maintenance are crucial. Here are some guidelines to follow:

- Read the manufacturer’s instructions carefully before installation to ensure correct wiring and setup.

- Mount the overload relay in a suitable location away from excessive heat, moisture, and vibration.

- Periodically inspect the relay for any signs of damage or wear. Replace worn-out components promptly.

- Conduct regular testing and calibration to verify the relay’s accuracy and functionality.

- Maintain a comprehensive record of maintenance activities and any modifications made to the system.

Overload relays are indispensable components for protecting electrical systems and equipment from overcurrent conditions. By promptly detecting and responding to excessive current flow, these relays prevent damage, optimize energy consumption, and enhance overall system performance. When selecting an overload relay, consider factors such as current rating, trip class, ambient conditions, and motor type to ensure optimal protection. By adhering to proper installation and maintenance guidelines, you can maximize the reliability and longevity of overload relays, thereby safeguarding your valuable electrical assets.

Overload relay, protect the motor or other load from damage in the event of a short circuit, or being over-loaded and overheating or phase Failure.

They have a built-in sensitive mechanism which protects the motor from overload and single phasing.

Overload relays have highly commendable functionality, longer functional life and robust construction. Also, relays have a high preference in the market.

Overload Relays A Safety Device for Steam Boilers FAQ

An overload relay is a safety device that protects electrical motors from overheating and damage. It does this by monitoring the current flowing through the motor and opening the circuit if the current exceeds a preset value.

Industrial steam Boiler motors are typically high-power motors that can draw a lot of current. If the motor were to overheat, it could damage the motor itself, the boiler, or even cause a fire. Overload relays help to prevent this by opening the circuit before the motor overheats.

Yes, overload relays are normally closed. This means that they are closed (or energized) when the motor is running normally. If the motor current exceeds the preset value, the relay will open (or de-energize), which will break the circuit and stop the motor.

Here are some precautions for using an overload relay in a Steam boiler:

Make sure that the overload relay is properly sized for the motor. The relay should have a current rating that is slightly higher than the motor’s full-load current.

Install the overload relay in a location where it will not be exposed to excessive heat or moisture.

Regularly inspect the overload relay for signs of wear or damage.

The purpose of an overload relay in a boiler is to protect the boiler motor from overheating and damage.

An overload relay works by monitoring the current flowing through the motor. If the current exceeds a preset value, the relay opens the circuit, which stops the motor.

There are two main types of overload relays: thermal overload relays and electronic overload relays. Thermal overload relays work by using a bimetallic strip to sense the temperature of the motor windings. If the temperature exceeds a preset value, the bimetallic strip bends and opens the circuit. Electronic overload relays work by using a sensor to measure the current flowing through the motor. If the current exceeds a preset value, the relay opens the circuit.

To size an overload relay for a boiler motor, you need to know the motor’s full-load current. The overload relay should have a current rating that is slightly higher than the motor’s full-load current.

The overload relay should be installed in a location where it will not be exposed to excessive heat or moisture. The relay should also be located where it is easily accessible for inspection and maintenance.

To maintain an overload relay, you should regularly inspect it for signs of wear or damage. You should also clean the relay and its contacts periodically

The safety precautions for using an overload relay in a boiler include:

Always use an overload relay that is properly sized for the motor.

Install the overload relay in a location where it will not be exposed to excessive heat or moisture.

Regularly inspect the overload relay for signs of wear or damage

You can buy an overload relay for your boiler from a number of different sources, including electrical supply houses, online retailers, and boiler manufacturers.

Buy Boiler Spare Parts at the Best Price

Thermodyne Boilers supplies 100+ Industrial Boiler Parts all over India. Contact our sales team & send your requirement to get prices & discounts