Coal Fired Boiler Manufacturer In India

What Is Coal Fired Steam Boilers

We are a leading manufacturer of industrial coal-fired steam boilers in India. Our boilers are made with high-quality components and state-of-the-art technology by our skilled professionals. They are widely used in the chemical, pharmaceutical, mining, construction, and metal fabrication industries.

Our boilers are manufactured in accordance with the stringent standards of the Indian Boiler Regulation codes. They are designed to withstand excessive thermal stresses. The boilers are made of boiler-grade steel plates and tubes. The quality is ensured during the manufacturing process itself, which reduces the number of rejections and reworks. All longitudinal and circumferential seams are X-rayed, and the boilers are stress-relieved as per IBR regulations before hydrostatic testin

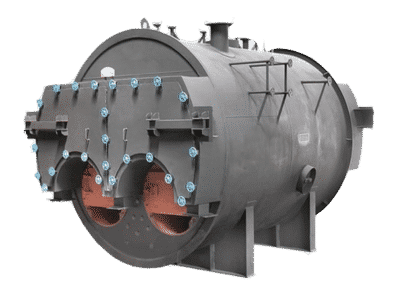

Coal Fired Steam Boiler

Our coal-fired steam boilers are inspected on multiple quality parameters to ensure that we deliver a flawless product. We use high-quality components and cutting-edge technology to manufacture our boilers in accordance with industry standards. We can also customize our boilers to meet the specific needs of our customers.

THERMIC FLUID HEATER: FLUIDTHERM (Wood/Coal Fired) (1 – 50 Lac Kcal Per Hour)

Coal Fired Steam Boilers in India: Cost-Effective Solutions from a Trusted Manufacturer

Coal-fired steam boilers are a reliable and cost-effective way to generate steam for a variety of industrial applications. In India, the demand for affordable and reliable coal fired steam boilers is crucial for various industries. Finding cost-effective solutions without compromising on quality is a priority.

Thermodyne is a trusted manufacturer of coal-fired steam boilers in India. We offer high-quality, affordable coal-fired steam boilers that meet the needs of our customers. Our boilers are manufactured using modern technology and creative design principles to lower production costs without sacrificing the efficiency and dependability of our boilers.

Benefits of choosing Thermodyne for your coal-fired steam boiler needs:

- High-quality boilers: We use high-quality materials and components to manufacture our boilers, ensuring that they are durable and reliable.

- Affordable prices: We offer competitive prices on our boilers, making them a cost-effective option for businesses of all sizes.

- Customizable solutions: We can customize our boilers to meet the specific needs of your application.

- Excellent customer service: We offer excellent customer service, from initial consultation to after-sales support.

The factors to consider when choosing a coal-fired steam boiler:

- Steam capacity: The steam capacity of the boiler should be sufficient to meet the needs of your application.

- Fuel type: The boiler should be compatible with the fuel that you will be using.

- Efficiency: The boiler should be as efficient as possible to save on fuel costs.

- Cost: The boiler should be affordable and within your budget.

- Warranty: The boiler should come with a warranty to protect you in case of any defects.

Thermodyne can help you choose the right coal-fired steam boiler for your needs. We offer a wide range of boilers to choose from, and we can customize a boiler to meet your specific requirements. Contact us today to learn more about our products and services

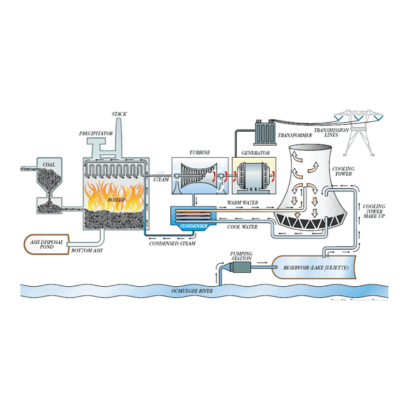

How does a coal fired boiler work?

Coal-fired boilers use coal to generate steam or hot water. Coal is burned in a combustion chamber, and the heat from the burning coal is transferred to water in a boiler vessel. The hot water is then converted to steam, which can be used for a variety of purposes, such as generating electricity, powering industrial processes, and heating homes and businesses.

Here is a simplified overview of how a coal-fired boiler works:

- Fuel supply: Coal is stored in a bunker or silo near the boiler and then transported to the combustion chamber by a conveyor system or other means.

- Combustion: The coal is mixed with a controlled supply of air in the combustion chamber. The air-coal mixture is carefully regulated to achieve efficient combustion.

- Ignition: An ignition source is used to start the combustion process. Once ignited, the coal burns, releasing heat energy.

- Heat transfer: The heat from the burning coal is transferred to the boiler vessel through a heat exchanger. The heat exchanger is made up of water-filled tubes or walls that absorb the heat from the burning coal and transfer it to the water.

- Steam generation: As the water absorbs heat, it eventually reaches its boiling point and turns into steam. The steam is collected in the boiler’s steam drum.

- Steam distribution: The steam is then piped out of the boiler to various applications, such as steam turbines in power plants, industrial processes, or for heating purposes in buildings.

- Exhaust gas: The remaining gases from the combustion process, including flue gases and ash particles, exit the boiler through a stack. In some cases, these gases may be treated to reduce emissions of pollutants.

- Ash removal: The solid ash particles left behind from the coal combustion settle at the bottom of the boiler or in ash hoppers. Periodically, these ashes are removed from the boiler for disposal or recycling.

Coal-fired boilers are equipped with sophisticated control systems to regulate fuel and air supply, maintain proper combustion conditions, and ensure safety and efficiency.

It is important to note that coal-fired boilers have faced increasing scrutiny and regulation due to their environmental impact, primarily the emission of pollutants such as sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter. In many regions, efforts have been made to improve the efficiency of these boilers and reduce their emissions, or they have been phased out in favor of cleaner and more sustainable energy sources.

Overall, coal-fired boilers are a reliable and efficient way to generate heat, but they also have a number of environmental drawbacks.

Advantages and Disadvantages of coal fired boiler

Advantages of coal-fired boilers:

- Reliable and efficient: Coal-fired boilers are a reliable and efficient way to generate heat. They can be used to generate large amounts of heat for a variety of applications.

- Abundant fuel source: Coal is a relatively abundant fuel source, and it is relatively inexpensive to mine and transport.

- Versatile: Coal-fired boilers can be used for a variety of applications, including power generation, industrial processes, and commercial and residential heating.

Disadvantages of coal-fired boilers:

- Environmental impact: Coal-fired boilers produce a number of pollutants, including sulfur dioxide, nitrogen oxides, and particulate matter. These pollutants can contribute to air pollution and climate change.

- Safety concerns: Coal-fired boilers can be dangerous if not properly operated and maintained. There is a risk of fires, explosions, and toxic gas emissions.

- Ash disposal: Coal ash is a byproduct of coal combustion that can be difficult and expensive to dispose of properly.

Overall, coal-fired boilers have a number of advantages, including reliability, efficiency, and abundance. However, they also have a number of disadvantages, including environmental impact, safety concerns, and ash disposal.

In recent years, there has been a trend towards switching from coal-fired boilers to cleaner and more sustainable alternatives, such as natural gas boilers and renewable energy sources. However, coal-fired boilers are still widely used in many parts of the world.

It is important to weigh the advantages and disadvantages of coal-fired boilers carefully before making a decision about whether or not to use them.

A coal-fired boiler is a type of boiler that burns coal to generate thermal energy, which can then be used to produce steam or hot water. Coal-fired boilers are commonly used in power plants, industrial settings, and for residential heating.

In a coal-fired boiler, coal is first crushed into a fine powder. This powder is then mixed with air and blown into the boiler’s combustion chamber. The coal burns in the combustion chamber, releasing heat. This heat is then used to heat water or steam.

Coal-fired boilers are relatively inexpensive to operate and maintain. They are also very efficient at converting coal into heat.

Coal-fired boilers are major contributors to air pollution. They also produce greenhouse gases that contribute to climate change.

Some of the major coal-fired boiler manufacturers in India include Bharat Heavy Electricals Limited (BHEL), Larsen & Toubro (L&T), and Thermax Limited.

There are many different types of industrial coal-fired boilers, but some of the most common include pulverized coal (PC) boilers, stoker-fired boilers, and fluidized bed combustion (FBC) boilers.

Industrial coal-fired boilers are used in a wide variety of applications, including power generation, steam production, and process heating.

The size, fuel type, and efficiency requirements of the application are all important factors to consider when selecting an industrial coal-fired boiler.

Some of the key KPIs for industrial coal-fired boilers include boiler efficiency, emissions, and maintenance costs.

The trend in industrial coal-fired boiler technology is towards more efficient and cleaner boilers. This is being driven by environmental regulations and the need to reduce operating costs.