Fluidtherm: Your Industrial Boiler Solution for Efficient Thermic Fluid Heating

“Thermic Fluid Heater are heating equipment, used in industry where heat transfers are primary need of process instead of pressure.” Thermic fluid heaters are heating equipment used in industry where heat transfers are the primary need of the process instead of pressure. They are typically used in applications where high temperatures and low pressures are required, such as in the food and beverage industry, the chemical industry, and the pharmaceutical industry.

Fluidthers are most efficient and highly effective equipment used in process heating which uses high viscous oil as a heating medium.

A thermic fluid heating system generally used in a system where the pressure is not desired in a process and temperature requirement is higher and using the boiler for high-temperature services may increase the cost of a project.

Thermal Fluid Heaters can improve process consistency and reduce downtime leading to a further increase in profitability.

Thermic Fluid Heater Manufacturer & Supplier

Our Company, Thermodyne Engineering Systems, manufacture thermic fluid heaters & heating systems that can be used to heat various fluids such as Thermal oil, Petroleum oil, Therminol, and even water.

Thermodyne supplied hundreds of thermic heating system equipment for various clients in India and exported to many companies.

Our product “Fluidtherm” is thermic fluid heater manufactured by thermodyne. To make purchase of fluidtherm contact our sales representations.

Industrial Applications of Thermic Fluid Heaters

Thermic fluid systems can be used to generate heat in various process industries, such as:-

- Food processing industries

- Rubber and plastics industries

- Publishing and print industries

- Metal fabrication and finishing plants

- Textile Industries

- Paper industries

- Textile industries

- Natural gas processing plants

- Crude oil extraction and processing industries.

- Chemical Industries

- Plywood and Laminates

- Confectionery

Thermic Fluid Heater Working & Design

Fluidtherm Construction Design

Fluidtherm, Thermic fluid heater, consists of two concentric coils in which inner coil acts as a radiation zone and outer coil act as a convection zone.

Flue gas velocity is generally higher between the 2 coils and between the coil and the outer shell, so higher the velocity higher will be the convective heat transfer between the flue gas and fluid.

Thermic fluid heaters can be made either 3 pass or 4 pass depending on the design of thermic fluid heater and the type of fuels to be burnt. The efficiency of the heater in

creases with an increase in the number of passes.

Working Process of Thermic Fluid Heaters

The maximum temperature of 350℃ of thermal fluid can be achieved in a Fluidtherm although the higher temperature of the thermal fluid can be achieved provided the temperature of fluid does not exceed the auto-ignition temperature.

Thermodyne, Fluidtherm – Thermic Fluid Heater also consists of a deaerator and expansion tank. The density of fluid decreases with increase in the temperature of fluid so a tank is generally installed in a process to help accommodate the extra volume of fluid which is increased due to increase in the fluid temperature. For every 100℃ rise in the fluid temperature, the volume of fluid increases by 7% so expansion tank is added to take care of that extra volume.

Deaerator tank is combined with the expansion tank and is generally used to vent out air from the fluid which acts as resistance in transferring heat to the fluid.

Industrial Thermic Fluid Heater Fuels

Fluidtherm, Thermic heating system made by thermodyne, can be used to burn the different type of fuels such as:-

Solid Fuels: Wood, Coal, Petcoke, Rice husk, etc.

Liquid Fuels: Light Diesel Oils, Heavy Oils, etc.

Gaseous Fuels: Natural Gas, Liquefied Petroleum Gas, etc.

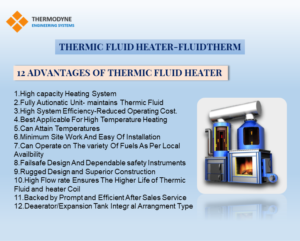

Advantages of Thermic Fluid Heaters

- High Capacity Heating System

- Fully automatic unit – Maintains the desired temperature of the thermic fluid

- High System Efficiency – Reduced operating cost.

- Best applicable for High-Temperature Heating

- Can attain temperatures upto 300 o C

- Minimum site work and ease of installation

- Can operate on the variety of fuels as per local availability

- Failsafe design and dependable safety instruments

- Rugged design and superior construction

- High flow rate ensures the higher life of thermic fluid and heater coil

- Backed by prompt and efficient after sales service

- Deaerator/Expansion Tank Integral Arrangement type

Fluidtherm Capacity

Fluidtherm is available in capacities from 1 Lac Kcal/hr to 50 Lac Kcal/hr

Advantages of Thermal fluid Heaters Infographics

Also Read: Water Treatment Chemicals

Thermic Fluid Heater ( Fluidtherm) Introduction Video

See More: Thermodyne boilers videos

Other Heating Products Manufactured by Thermodyne

Thermic fluid heater PPT

Thermic Fluid Heater FAQ

1 .What is a thermic fluid heater?

A thermic fluid heater is a type of industrial heating equipment that uses a heat transfer fluid to transfer heat from a combustion process to a desired process. The heat transfer fluid is typically a synthetic oil or a synthetic glycol, and it is circulated through the heater in a closed loop.

2 .What are the different types of thermic fluid heaters?

There are two main types of thermic fluid heaters: liquid phase and vapor phase. Liquid phase thermic fluid heaters use a flooded pressure vessel to heat the heat transfer fluid without vaporization taking place in the vessel. Vapor phase thermic fluid heaters use a heater for vaporizing the fluid internally within the vessel.

3. What are the benefits of using a thermic fluid heater?

There are many benefits to using a thermic fluid heater, including:

High efficiency: Thermic fluid heaters are very efficient, and they can save energy costs.

Low maintenance: Thermic fluid heaters are relatively low-maintenance, and they require little downtime.

Wide range of applications: Thermic fluid heaters can be used to heat a wide variety of materials, including liquids, gases, and solids.

Environmentally friendly: Thermic fluid heaters are a clean and environmentally friendly way to heat materials.

4. What are the drawbacks of using a thermic fluid heater?

The main drawbacks of using a thermic fluid heater are:

High initial cost: Thermic fluid heaters are more expensive than other types of heating equipment.

Complex installation: Thermic fluid heaters are more complex to install than other types of heating equipment.

Potential safety hazards: Thermic fluid heaters can pose a potential safety hazard if they are not properly installed and operated.

5. What are the different types of heat transfer fluids used in thermic fluid heaters?

The most common type of heat transfer fluid used in thermic fluid heaters is a synthetic oil. Synthetic oils are non-toxic, non-flammable, and have a high boiling point. Other types of heat transfer fluids that can be used in thermic fluid heaters include water, glycol, and molten salts.

6. How do thermic fluid heaters work?

Thermic fluid heaters work by circulating a heat transfer fluid through a closed loop system. The heat transfer fluid is heated by a combustion process, and it then transfers the heat to the material that needs to be heated. The heat transfer fluid is then circulated back to the heater, where it is heated again.

7. What are the different applications of thermic fluid heaters?

Thermic fluid heaters can be used in a wide variety of applications, including:

Food processing

Chemical processing

Pharmaceutical manufacturing

Metalworking

Textile manufacturing

Paper manufacturing

Power generation

Wastewater treatment

8 . What are the different safety considerations for thermic fluid heaters?

Thermic fluid heaters can pose a potential safety hazard if they are not properly installed and operated. Some of the safety considerations that should be taken into account when using thermic fluid heaters include:

Proper installation and commissioning by a qualified technician

Regular inspection and maintenance by a qualified technician

Use of the correct type of heat transfer fluid

Proper ventilation to prevent the buildup of fumes

Proper training of personnel who will be operating and maintaining the thermic fluid heater

9 .What are the different types of controls used in thermic fluid heaters?

Thermic fluid heaters can be controlled using a variety of different types of controls, including:

Manual controls

Pneumatic controls

Electronic controls

The type of control that is used will depend on the specific application and the requirements of the user.

10. What are the different types of safety devices used in thermic fluid heaters?

Thermic fluid heaters can be equipped with a variety of different safety devices, including:

High-temperature alarms

Low-level alarms

Pressure relief valves

Flame failure controls

The type of safety devices that are used will depend on the specific application and the requirements of the user.

Thermic fluid heater

Boiler resources

Boiler Spare Parts Links Here